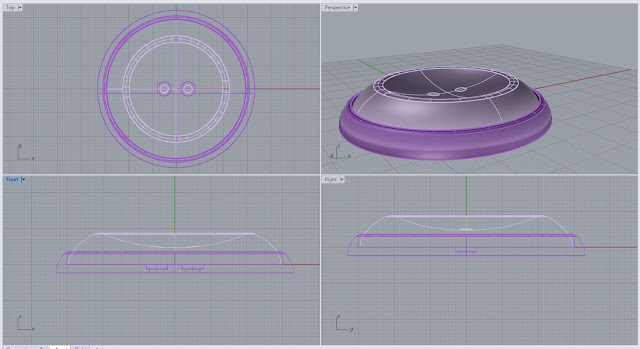

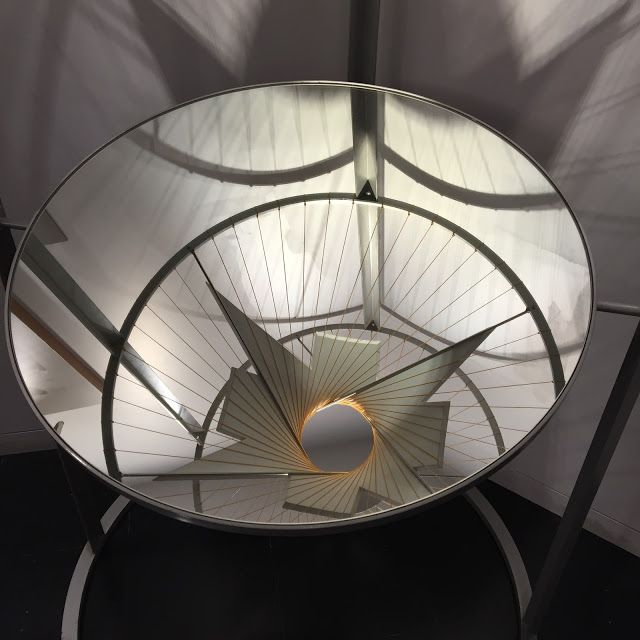

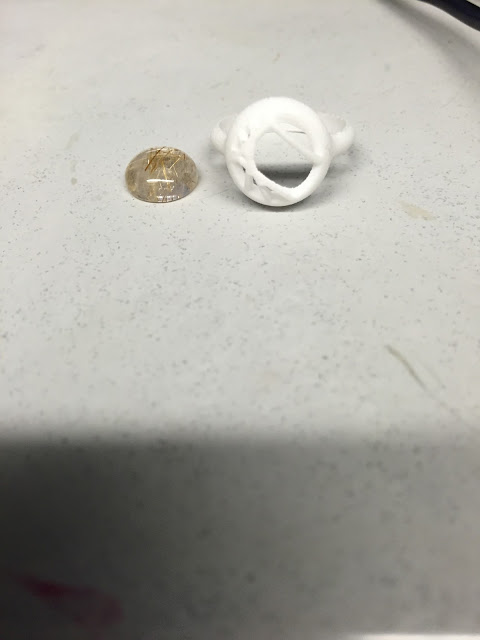

I recently re-discovered this 3D-printed PLA dish prototype made by an Intern, Becca Young, in Spring 2018. When this was made we were working on a number of projects that featured sacred geometry. This dish design was intended to be part of a line of interior home-goods. The project has yet to be realized as it was intended, however, when I was looking at it today, my interpretation of it changed as a result of the time passed. It’s interesting to see desires manifest and perceptions of them evolve over time to fit the present moment…

Connect

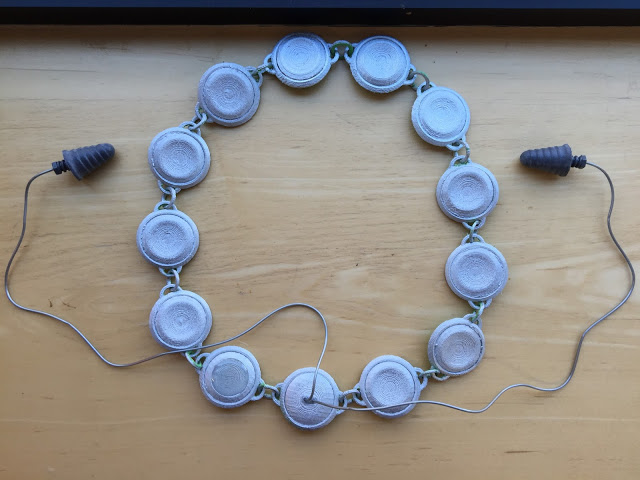

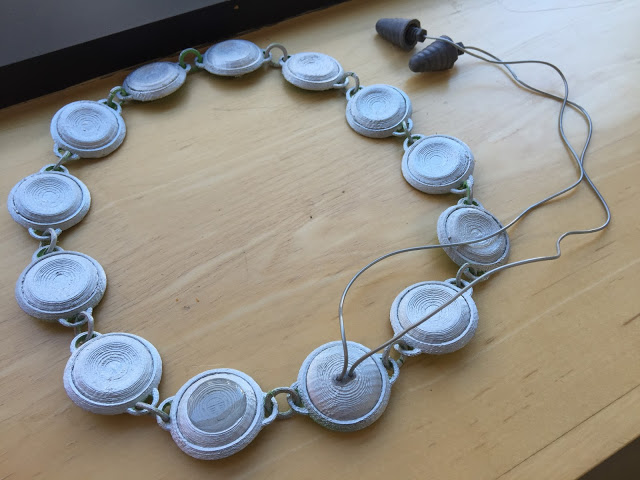

Last week I installed a number of the iAm series pieces "buffet style" in a gallery space. I invited some friends in and asked them to interact with the pieces. The event resulted in some new inspirations and a lot of laughs.

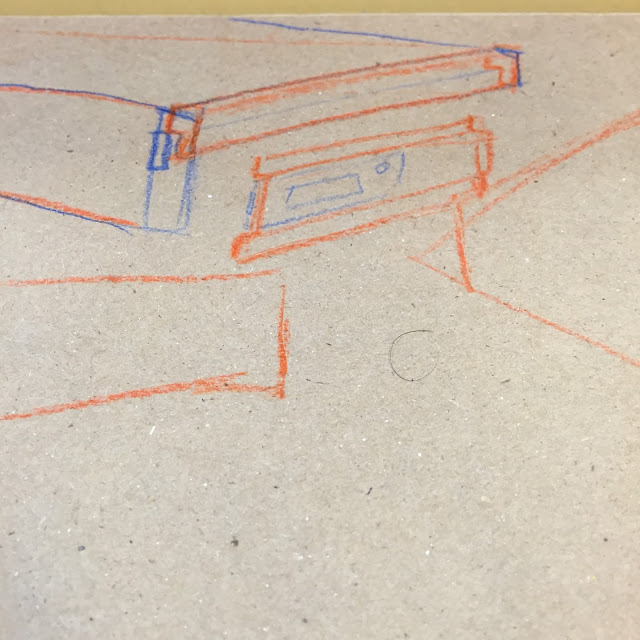

a new component

Someone will have to hold this.

More Jacks Prototype

judgment, expectation, connection, resistance, hinders communication, misunderstood, tension, stagnation

sprinkle, shower, rain, drain, pour, flow - but no

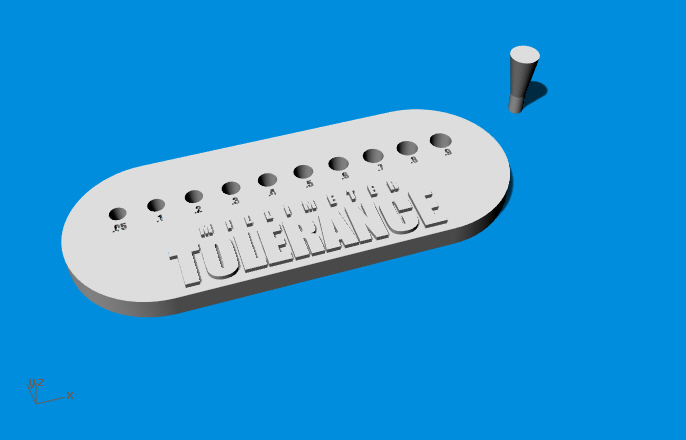

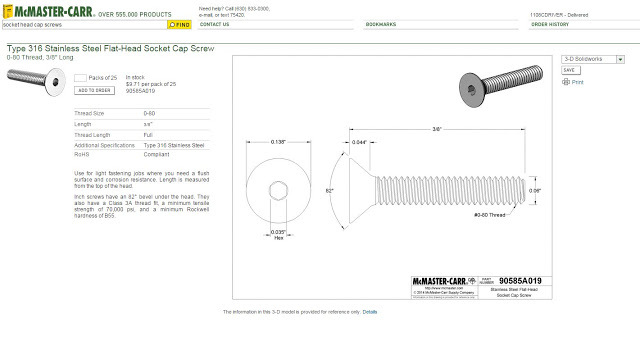

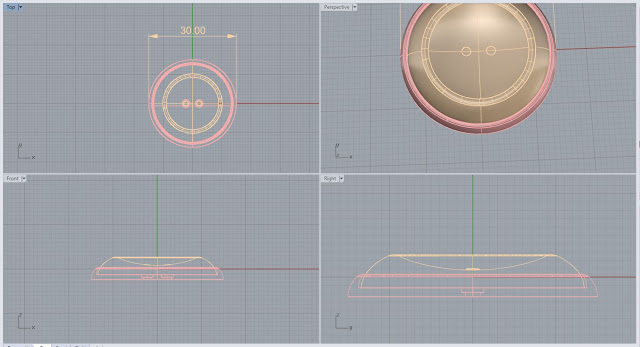

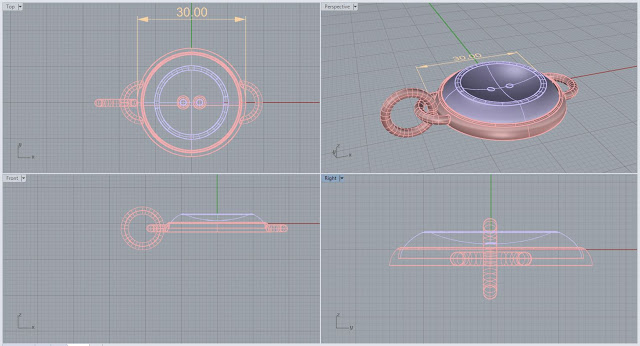

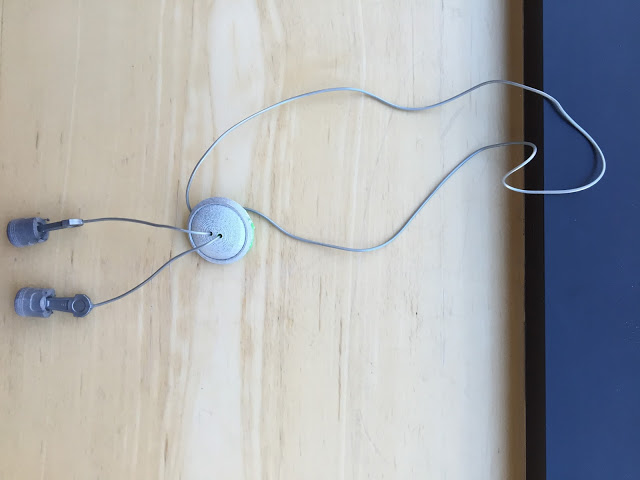

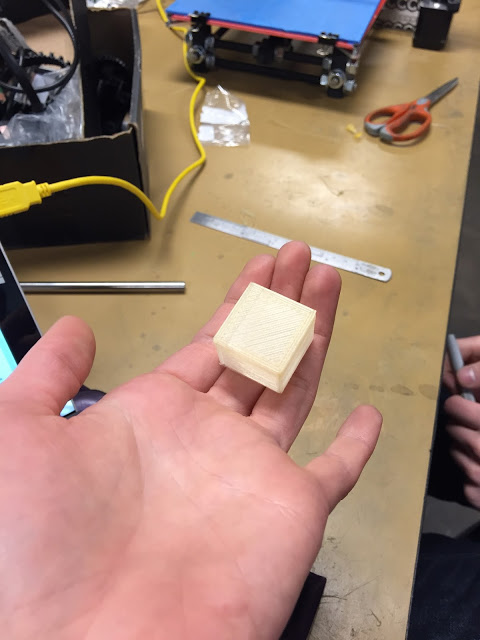

Millimeter Tolerance Sample

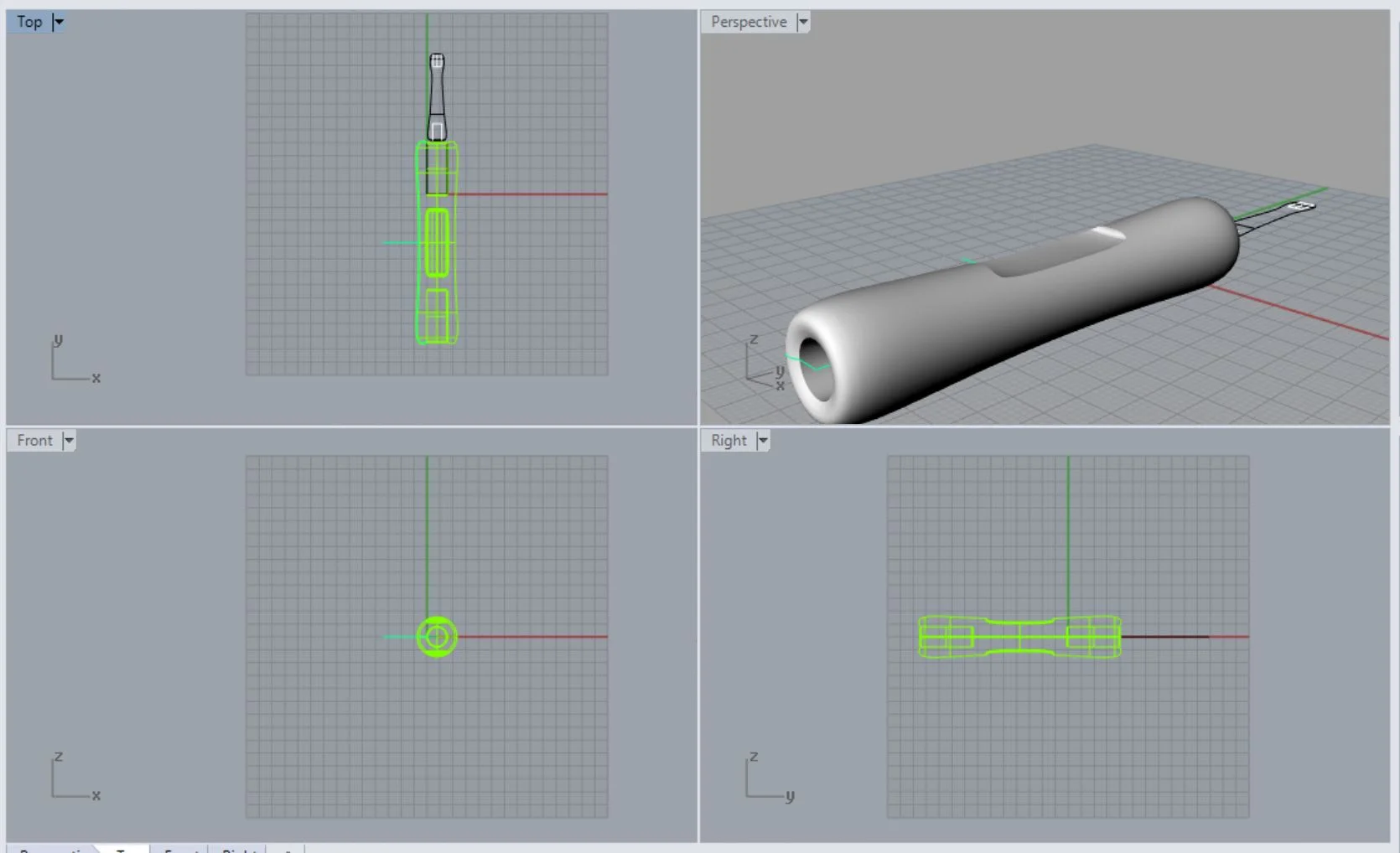

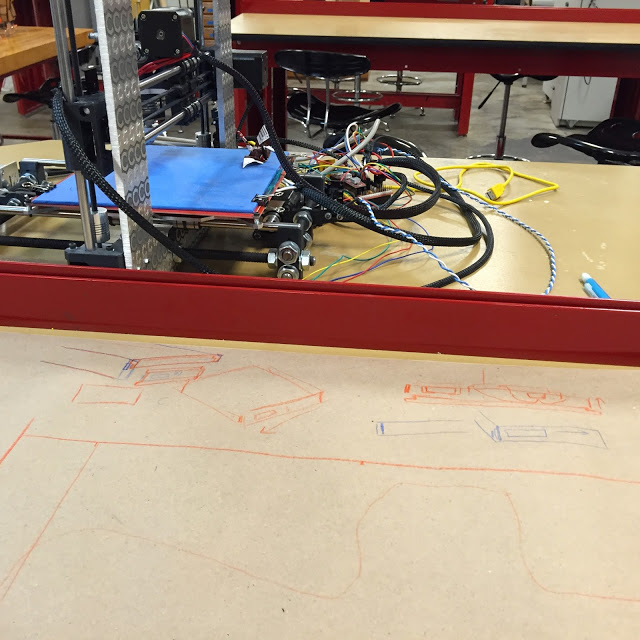

We got a couple new Qidi Technology 3D printers in the lab this semester. I prepared and printed a tolerance sample for my student's jewelry project that is coming up in a few weeks. If you would like one too, find the files on Thingiverse and here; .3dm & .stl 1 & .stl2

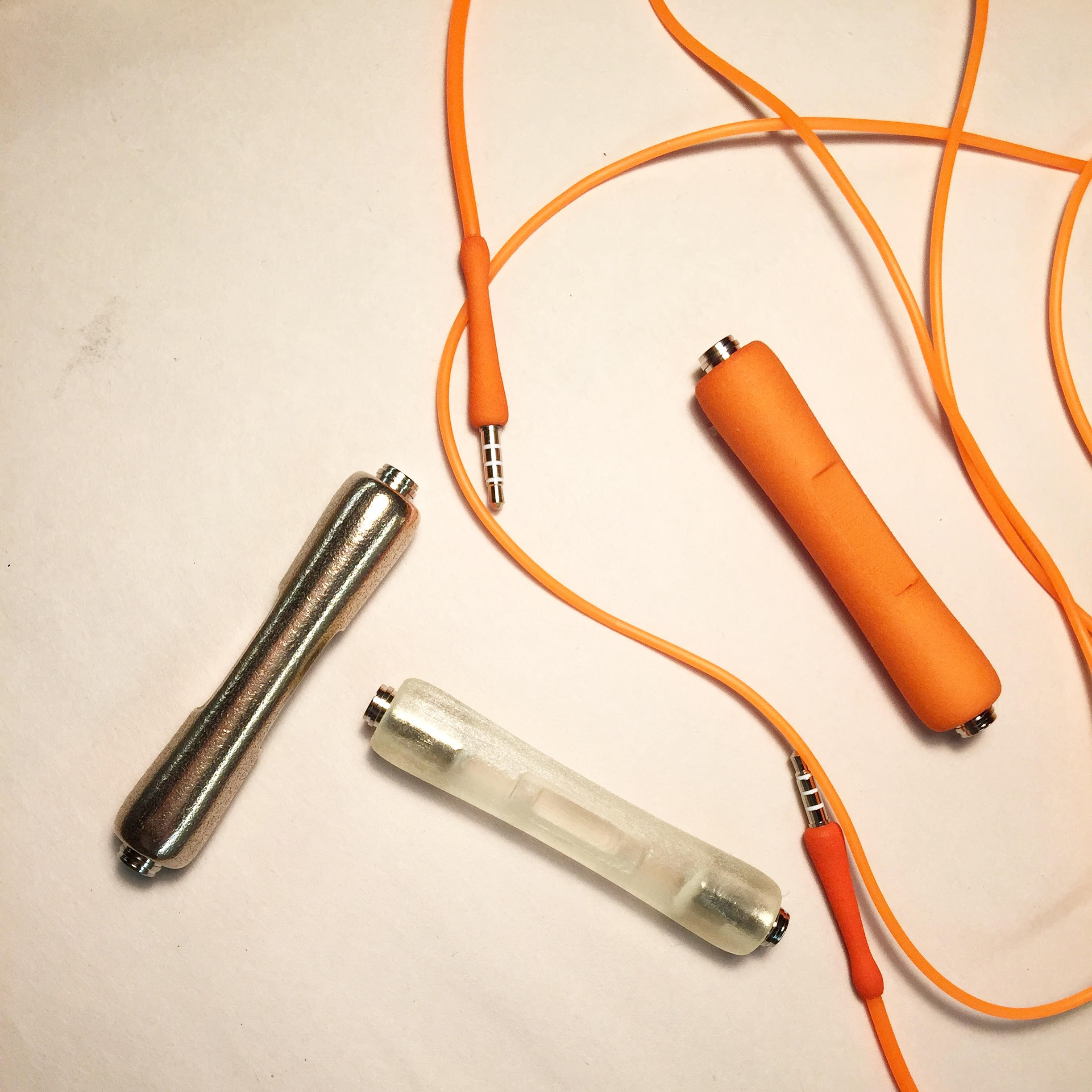

Universal Connections

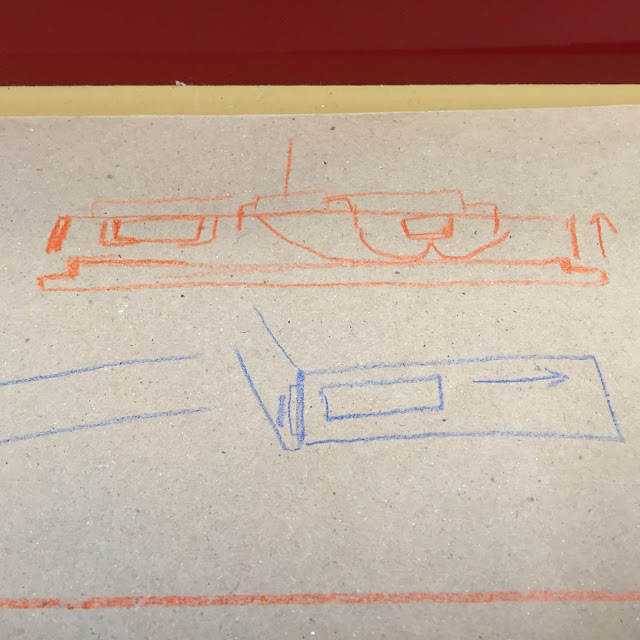

I've been designin', I've been designin'. I get antsy when I'm waiting on 3D prints.

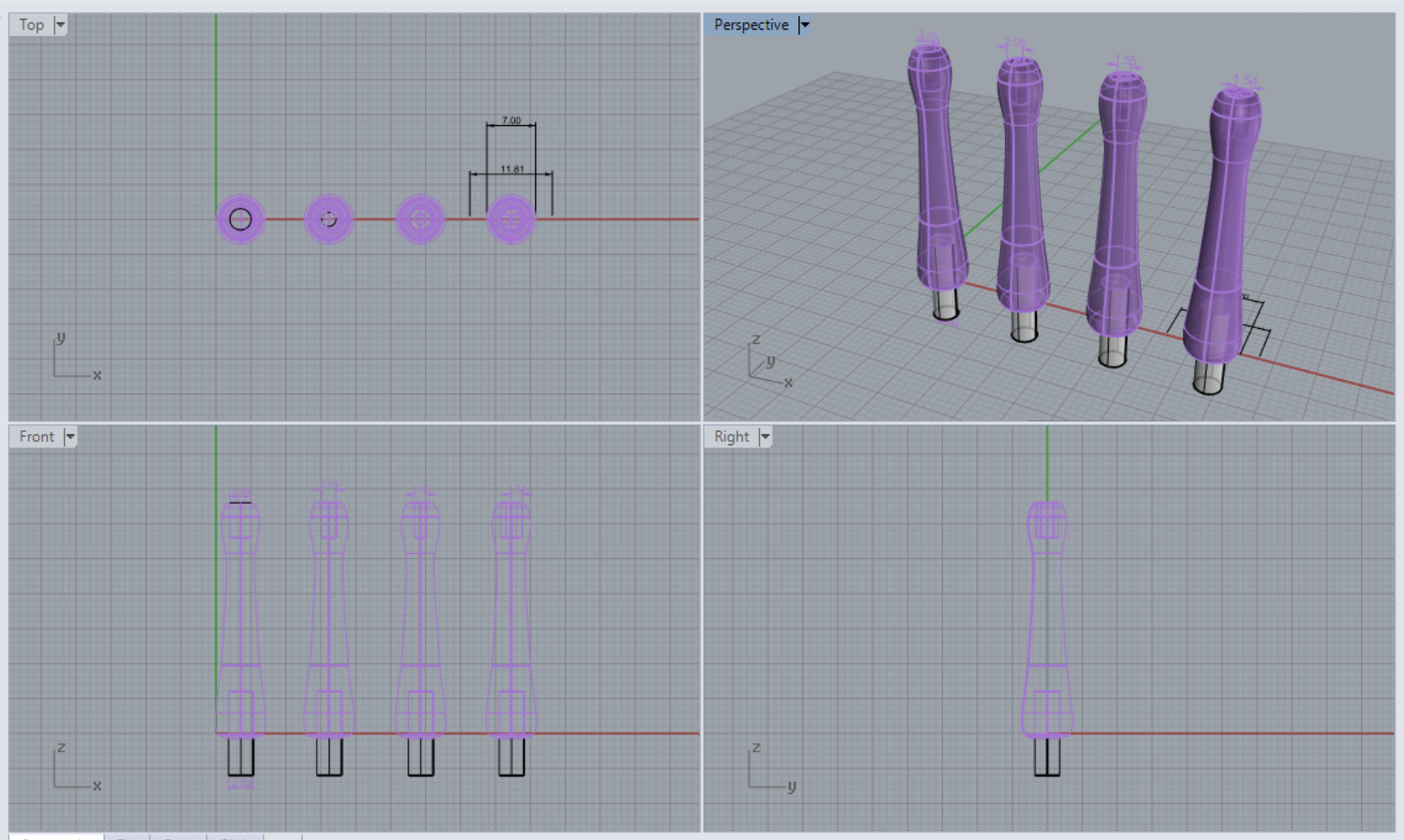

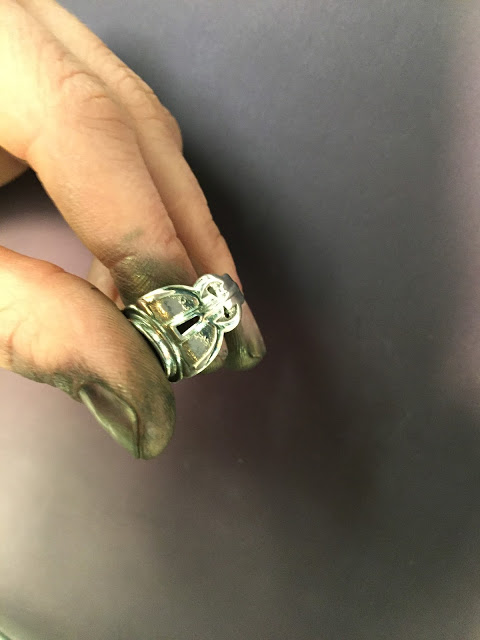

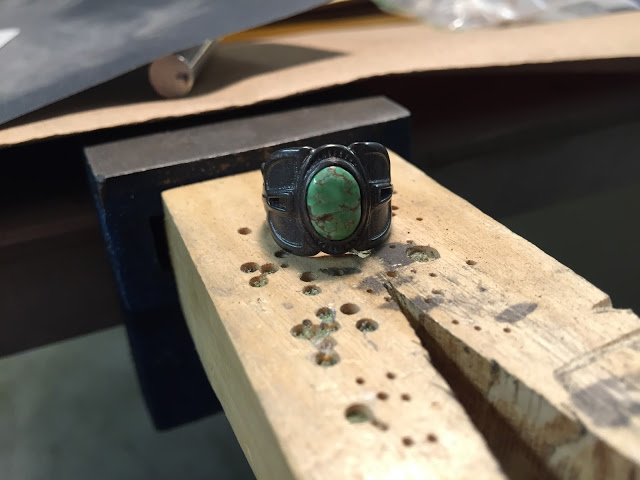

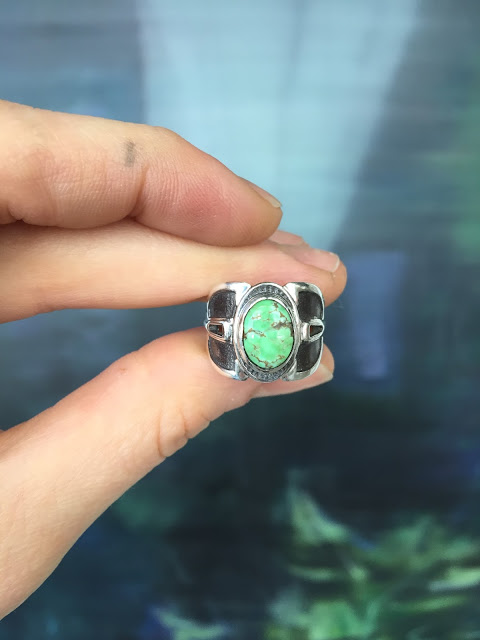

Ring Samples

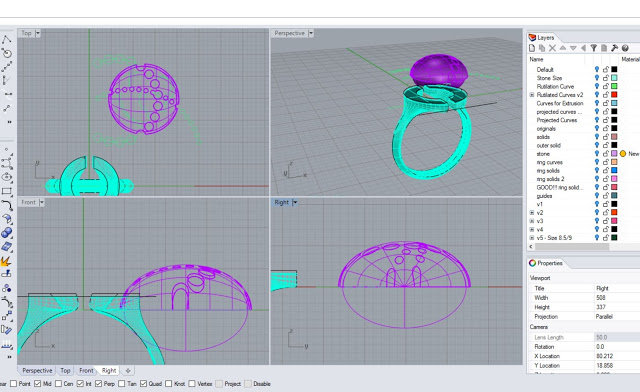

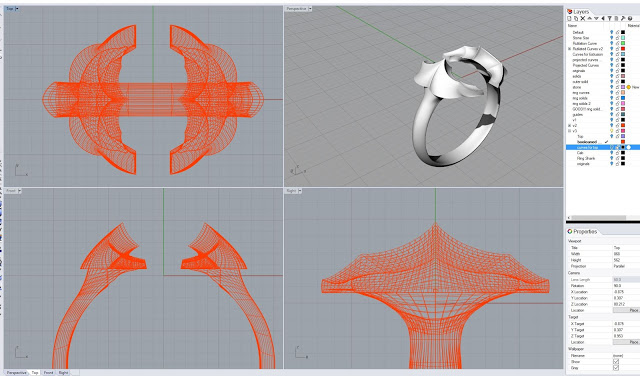

I went into the summer with some Rhino goals in mind, and I've been slowly working through a few of them with a series of ring samples. One of the goals was to increase my "organic" design skills, so I started with exploring curve networks. Coupling these curve networks with some solid primitive forms got me some simple but effective sample ring designs I was able to upload to Shapeways and get printed in a variety of materials. I think these samples will also be helpful to my students in ART277. I got various ring sizes printed to check the tolerances of printing, attempted to incorporate a "tension" held rutilated quartz stone and pushed scale limits. I've gotten about half of the rings from Shapeways, see below. TBC.

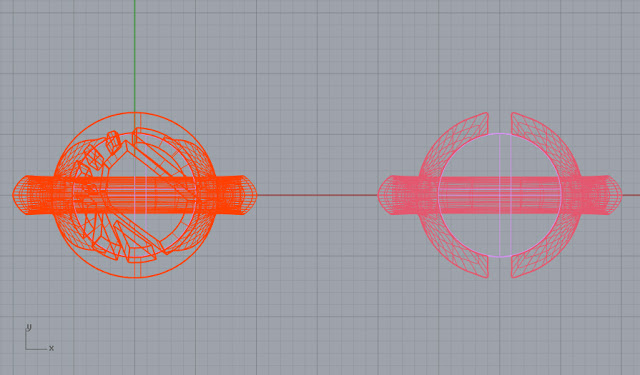

On the right in Pink - a stock band I created with curve network, attached to all ring samples. Left - Rutilated capture ring.

Process capture of creating designs from solids.

With this ring, I tried to go as tight as possible to the minimum limit of material thickness for the top design. I'm calling it the "bite ring." I learned a lot trying to create the curve network for the top.

The aluminum plastic on the left is hilarious to me because the design I created is meant to reference hammer texture. Oh, metalsmith humor.

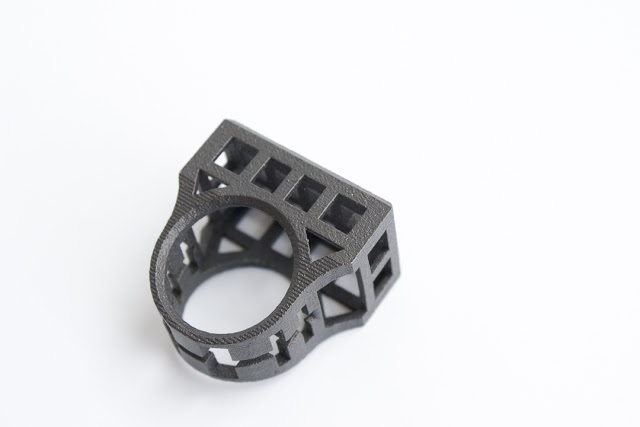

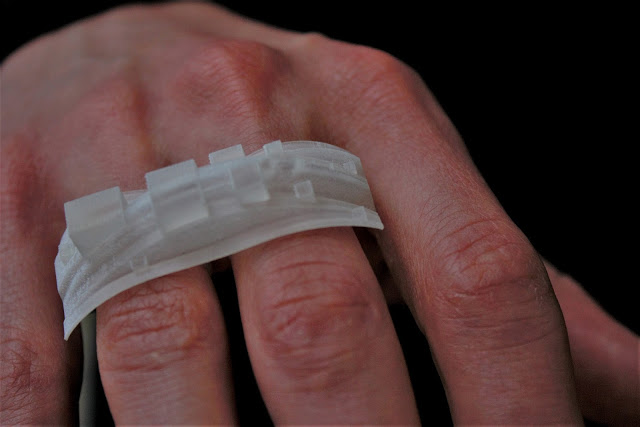

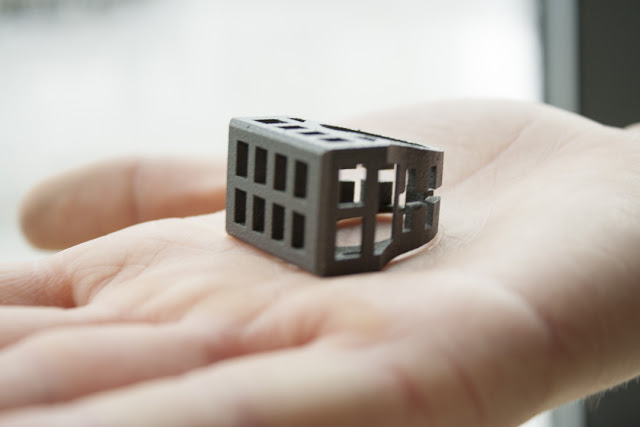

Design for Digital Fabrication - Student Work - 3D Printed Ring Documentation off the Body

3D Printed Architecture Inspired Ring

For this project, students used Rhino to design a ring inspired by architecture. Students printed their own preliminary ring size tests on the Makerbots in the DCRL, and then got the final designs printed through Shapeways. They all fit!

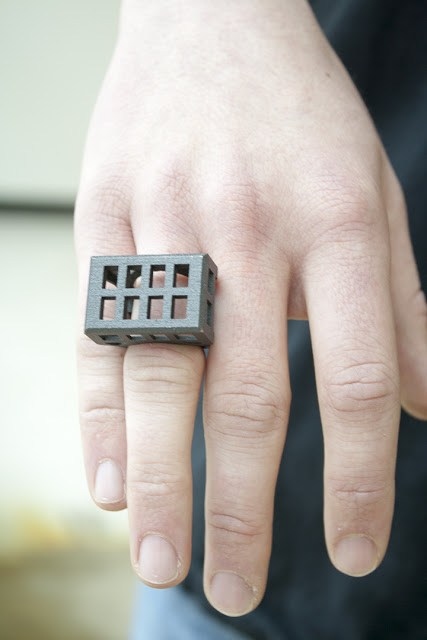

Design for Digital Fabrication - Student Work - 3D Printed Ring Documentation on the Body

3D Printed Architecture Inspired Ring

For this project, students used Rhino to design a ring inspired by architecture. Students printed their own preliminary ring size tests on the Makerbots in the DCRL, and then got the final designs printed through Shapeways. They all fit!

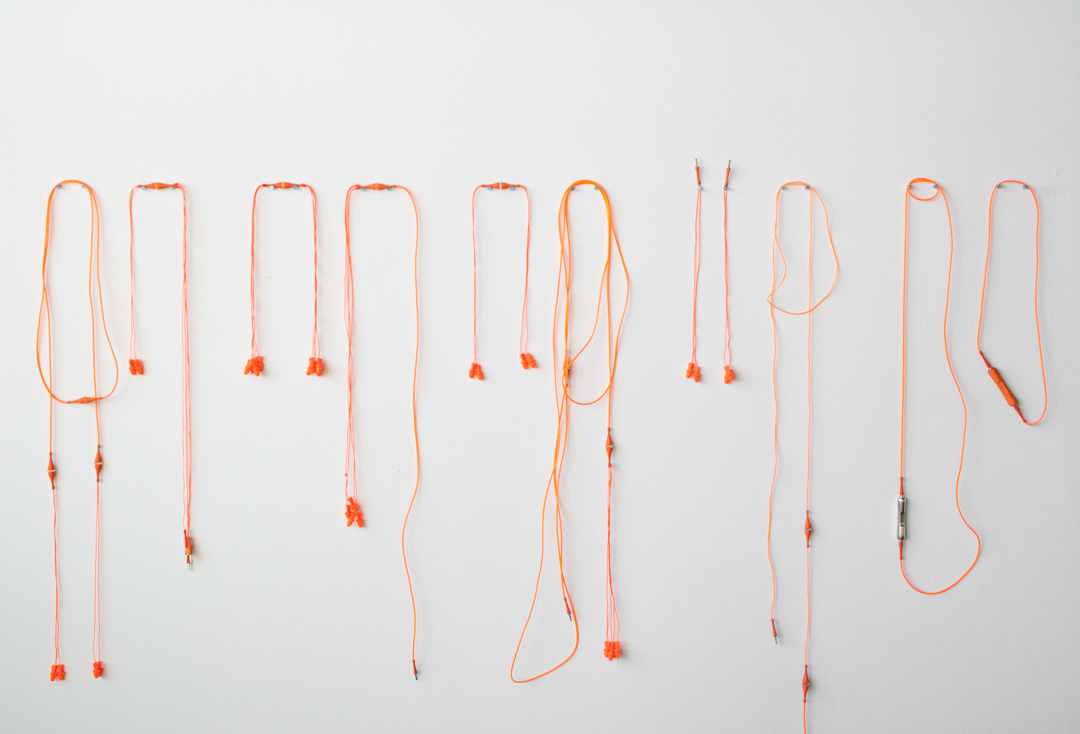

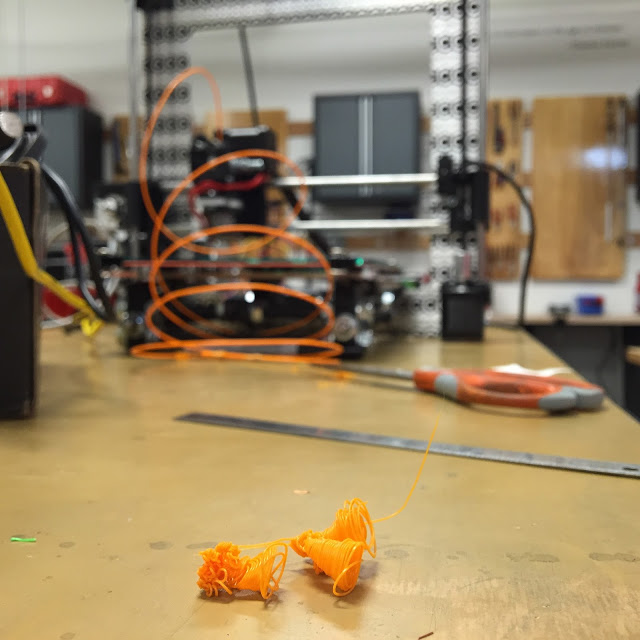

3D Prints for The Collaboratory

I love orange filament. Go check out the Pieper Family Education Gallery to see all of the work in The Collaboratory installation.

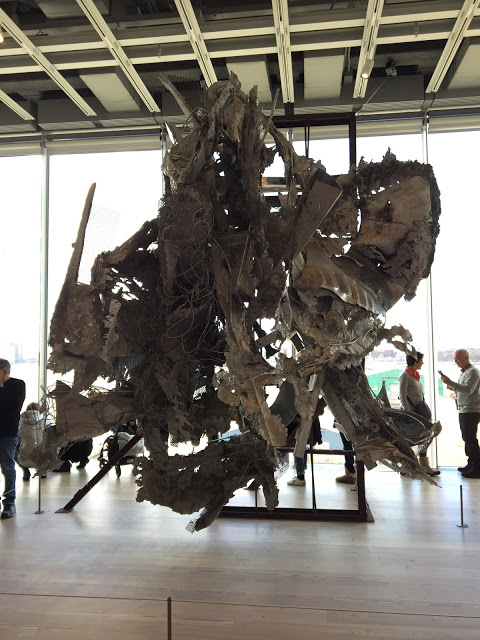

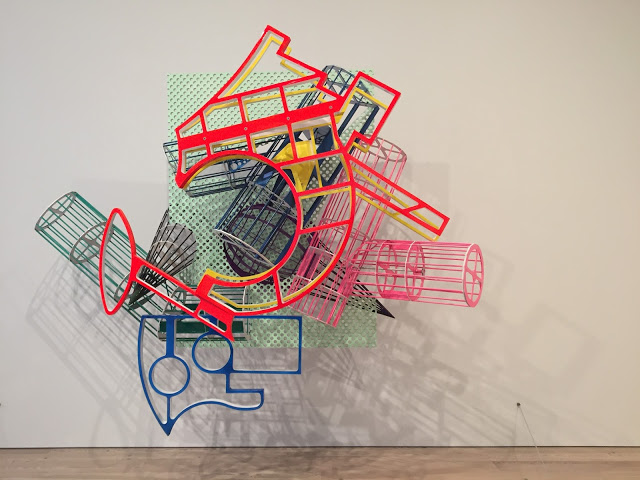

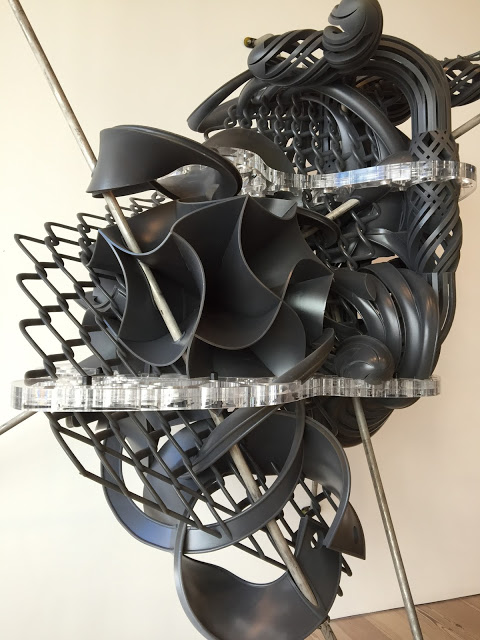

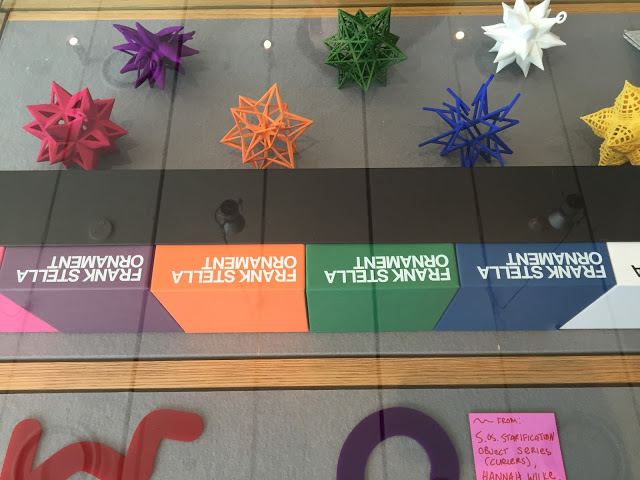

DFD & Frank Stella's Retrospective

|

| La penna di hu, 1987-2009 Mixed media on etched magnesium, aluminum and fiberglass |

|

| La penna di hu, 1987-2009 Mixed media on etched magnesium, aluminum and fiberglass -- Side View |

|

| K.459, 2012 Tusk SolidGrey 3000, plexiglass, and steel pipe |

|

| K.459, 2012 Tusk SolidGrey 3000, plexiglass, and steel pipe |

|

| K.459, 2012 Tusk SolidGrey 3000, plexiglass, and steel pipe |

|

| K.459, 2012 Tusk SolidGrey 3000, plexiglass, and steel pipe |

|

| Circus of Pure Feeling for Malevich, 4 Square Circus, 16 Parts,2009 Stainless steel tubing, wire, Protogen RPT |

|

| Circus of Pure Feeling for Malevich, 4 Square Circus, 16 Parts,2009 Stainless steel tubing, wire, Protogen RPT |

|

| And of course, some 3D printed Stella ornaments in the gift shop -- Stella knows what's up. |

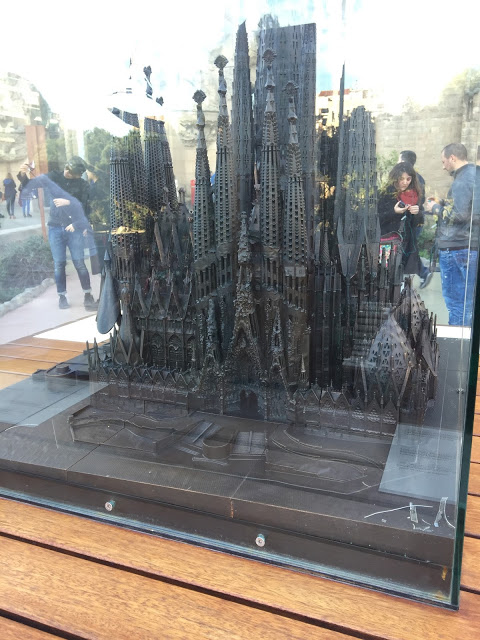

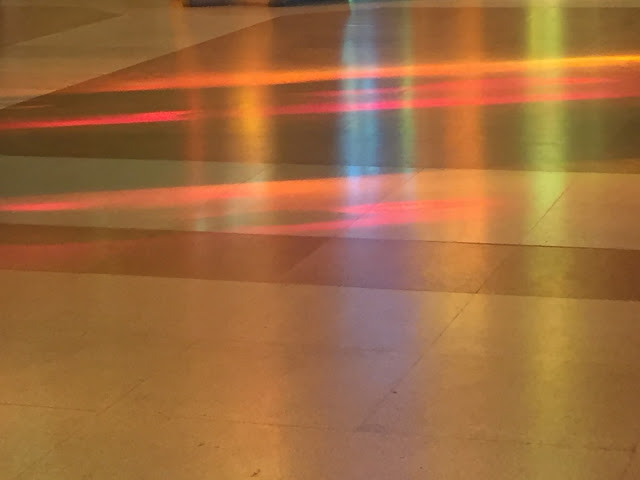

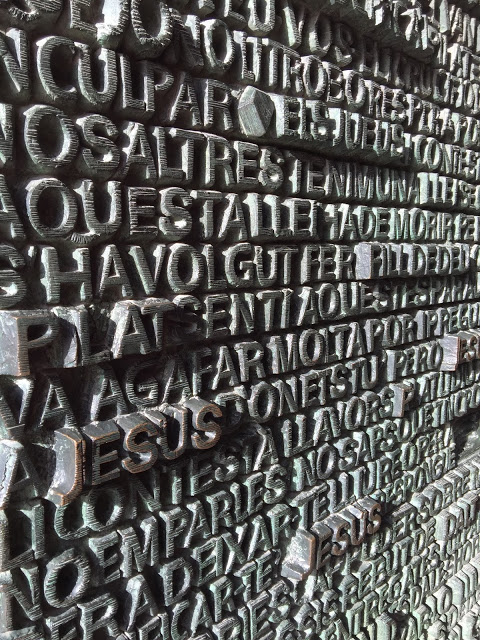

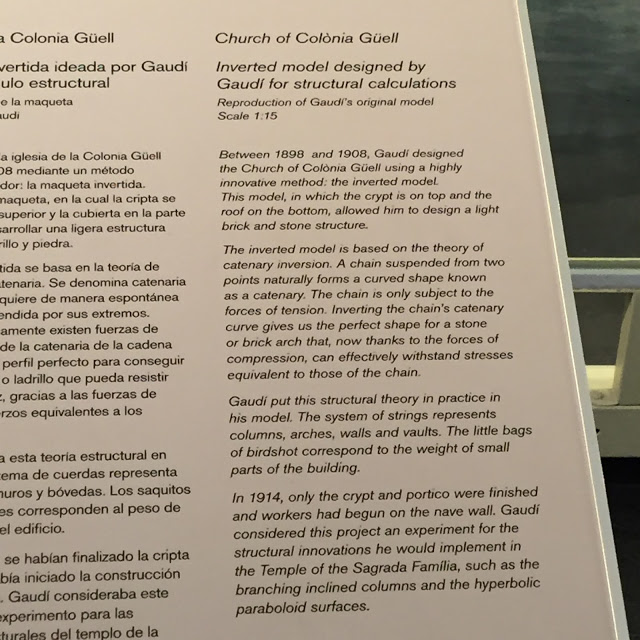

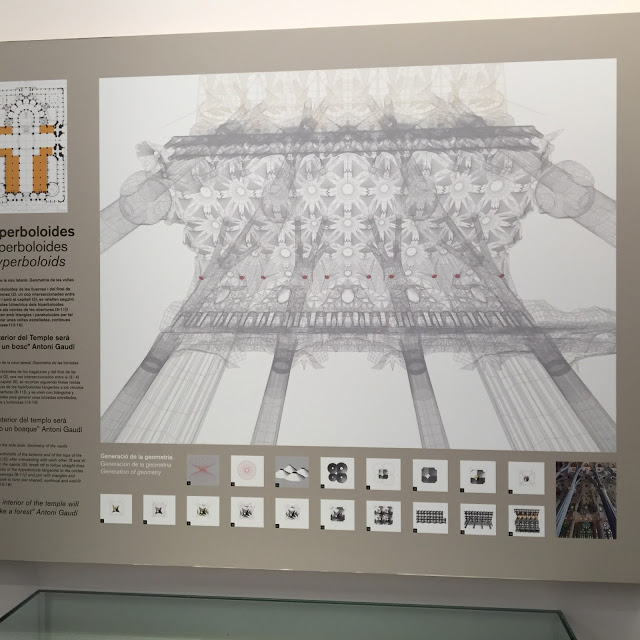

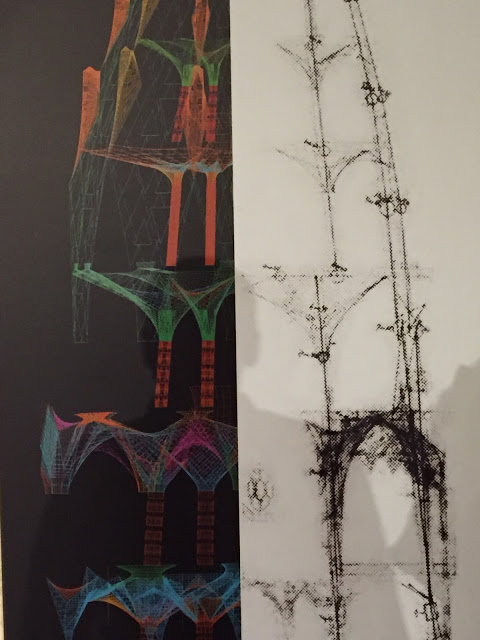

Basilica de la Sagrada Familia - Antoni Gaudi

I absolutely loved how the lights on the capitals reminded me of cabochon jewels, but also fruit hanging from the palm trees.

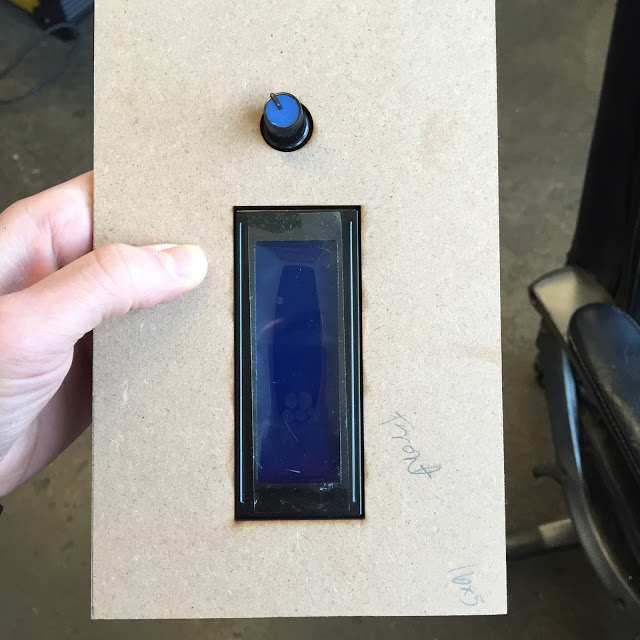

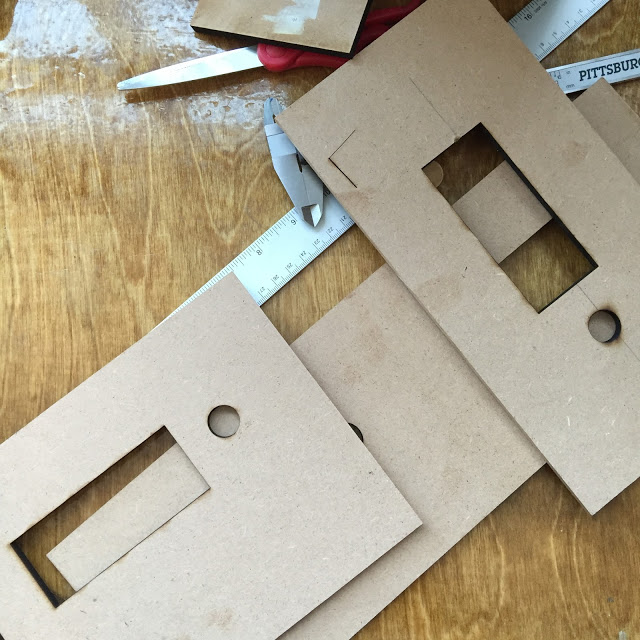

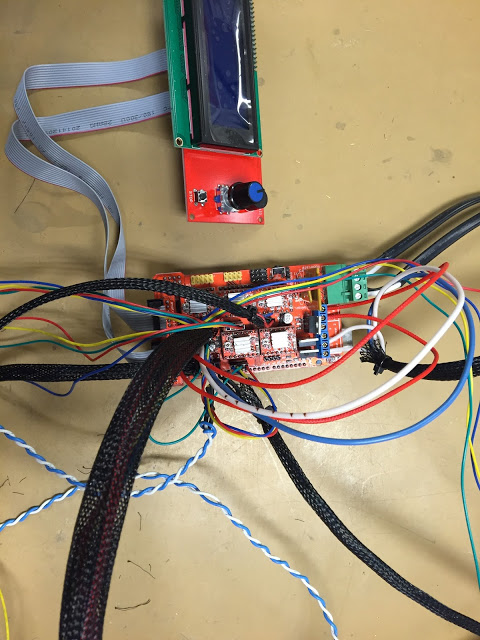

Making a 3D Printer - Control Box

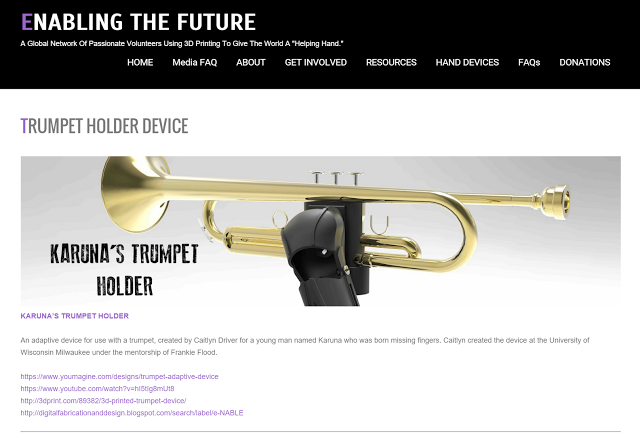

E-Nable Fellowship - Trumpet Files on enablingthefuture.org

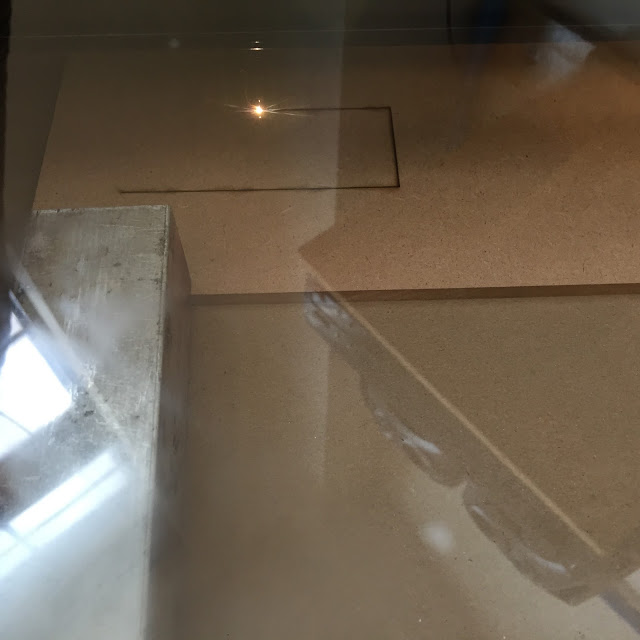

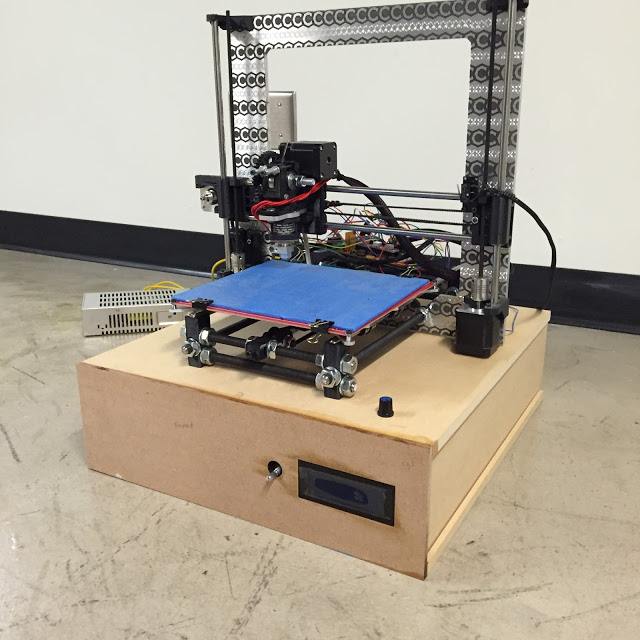

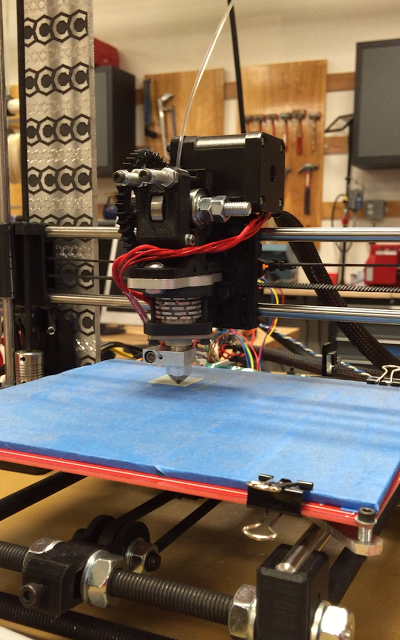

Making a 3D Printer - Prusa i3 progress

|

| My real first print. |

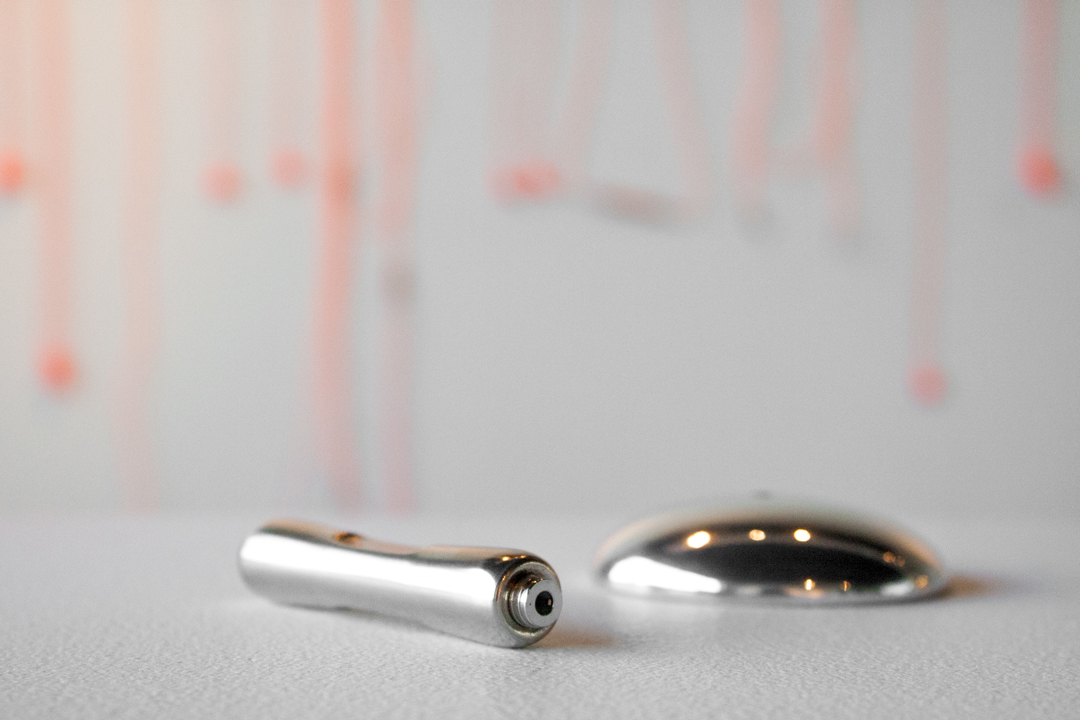

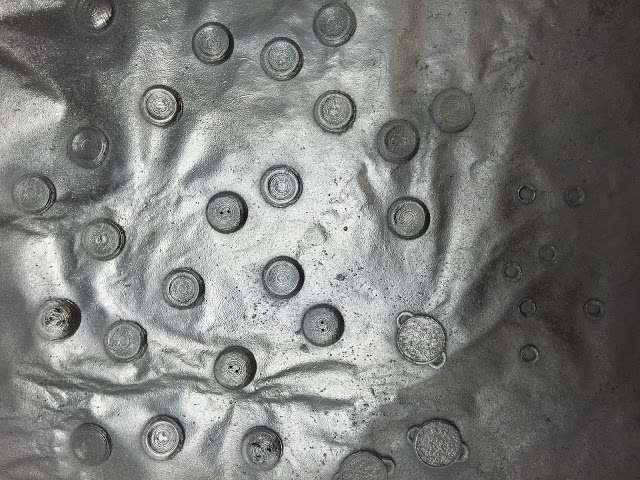

iAm Samples - Design for CNC Machining

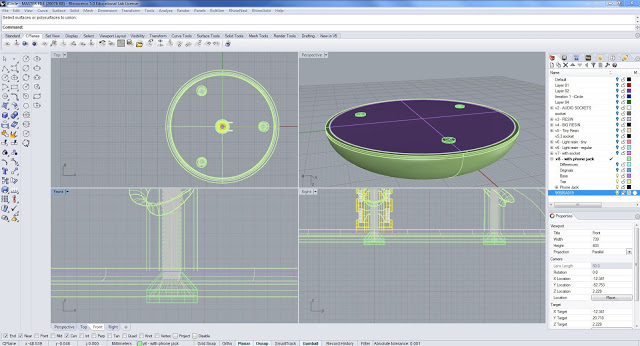

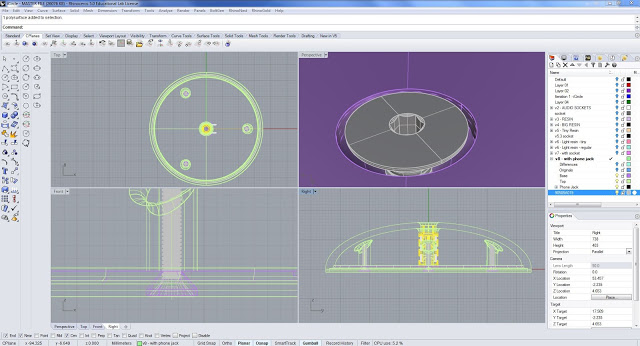

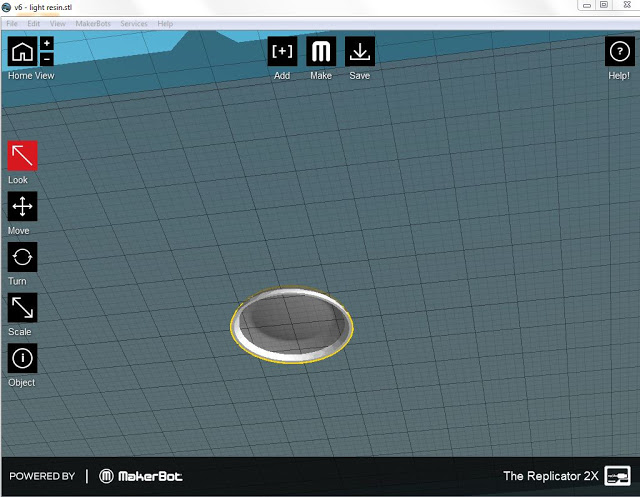

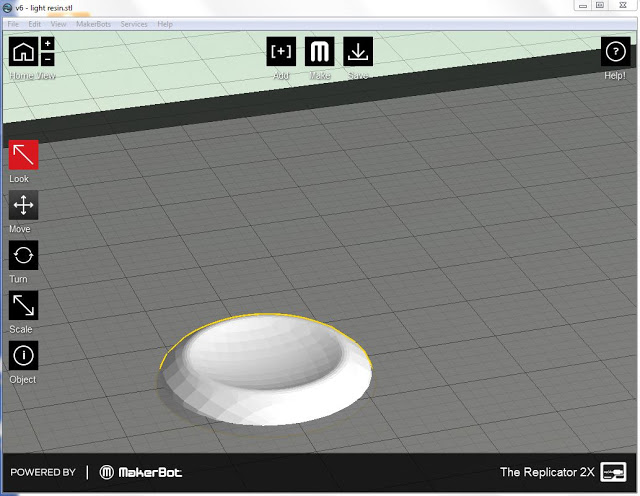

iAm samples - light + resin

iAm - samples - resin experiment