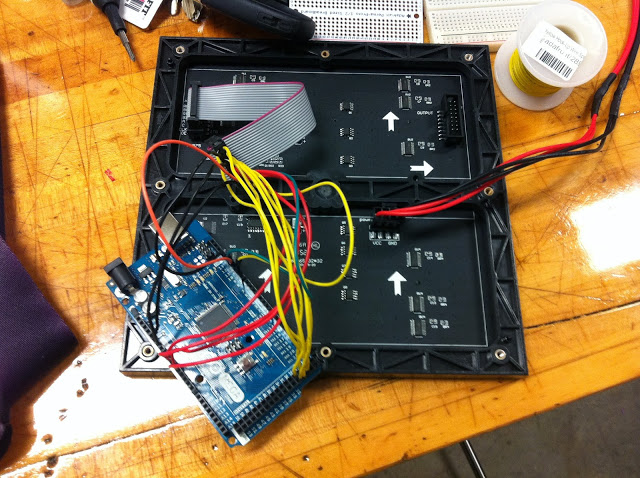

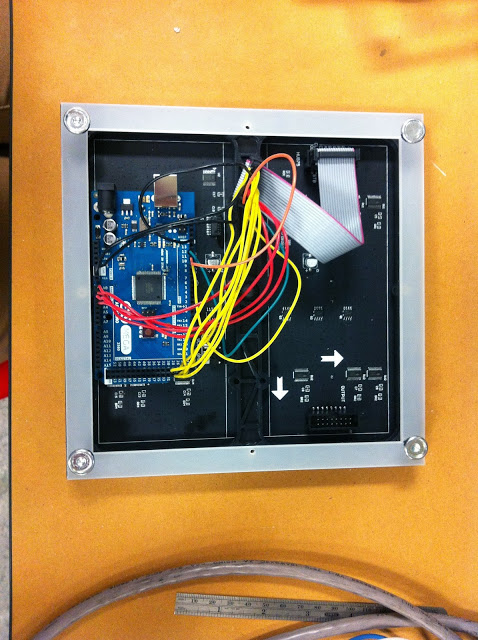

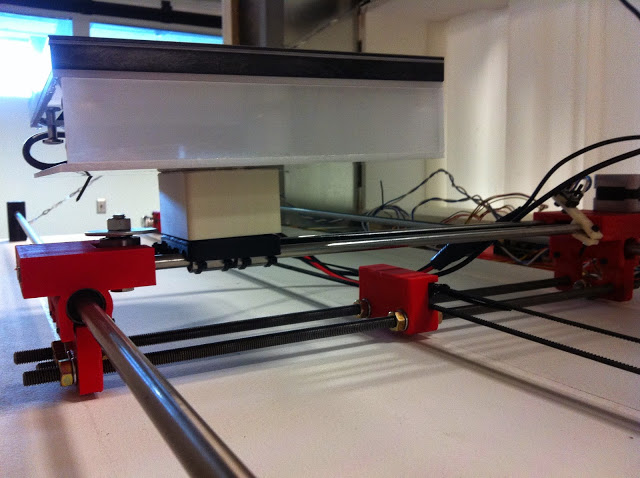

Today, I wired up the LED Matrix for the short axis carriage and designed the mount. The mount is made out of 1/8" acrylic that I laser cut to size. I tapped screw holes for the 2mm screws that came with the LED Matrix for constructing. I welded all of the acrylic parts together with Weld On. I then designed a space for the light to sit further elevated off of the carriage - so that I get the maximum travel distance out of the short axis. The new modified mount works well with the endstop. I've also uploaded a couple videos of the machine in action from when I was testing out code for the movement and the light pattern. I'm pretty happy with the progress... Even though it is doing something completely different than what I envisioned it would do.

Machines that Make - Structure - Part 2

Machines that Make - Structure

Over the weekend I started to build the wall that will house my Machine that Makes project. There is a steel stud frame, plywood, sheet metal, lots of metal screws, more plywood etc. I added a hinge to the back panel that will hold the steel rods that make up my machine, for easy access. Eventually, I will also add some trim over the shims that surround the acrylic. Next step is to fill the screw holes in the plywood, sand and paint.

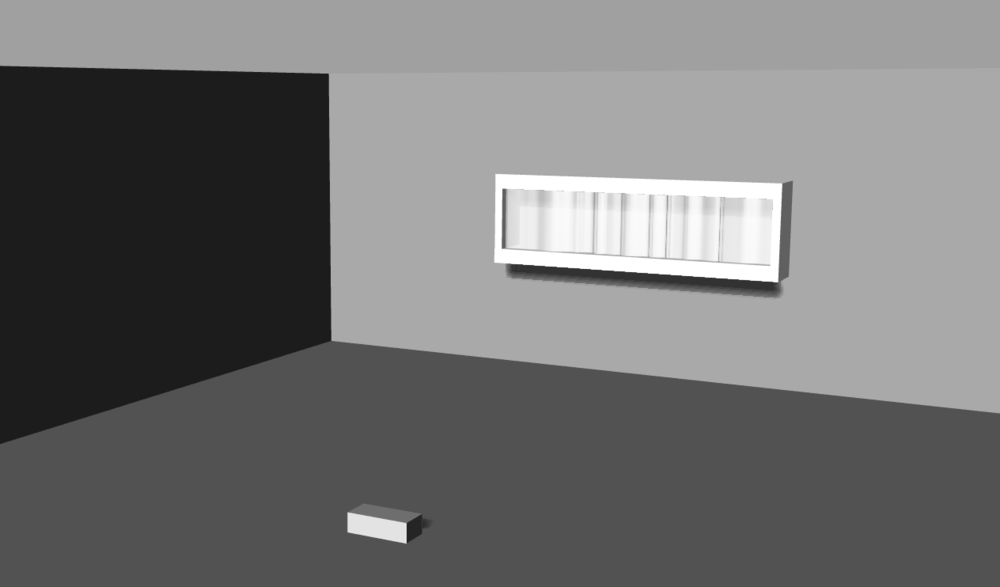

Machines that Make - Digital Renderings

For graduate reviews, I created a digital rendering of the machine I am creating this semester to help communicate my ideas and work-in-progress. I enjoyed working in Rhino to create a model of what I am envisioning in my head. I also really enjoyed learning more about how to use the lighting features in Rhino to create a more realistic rendering.

I am thinking that the materials that construct the "lamp shade" will be drywall or wood, painted to match the wall. The box across the way will house the Kinect, that will track the movement of the viewer and initiate the movement of the motorized gantry that holds the end effector (light).